DDRH-DDVL

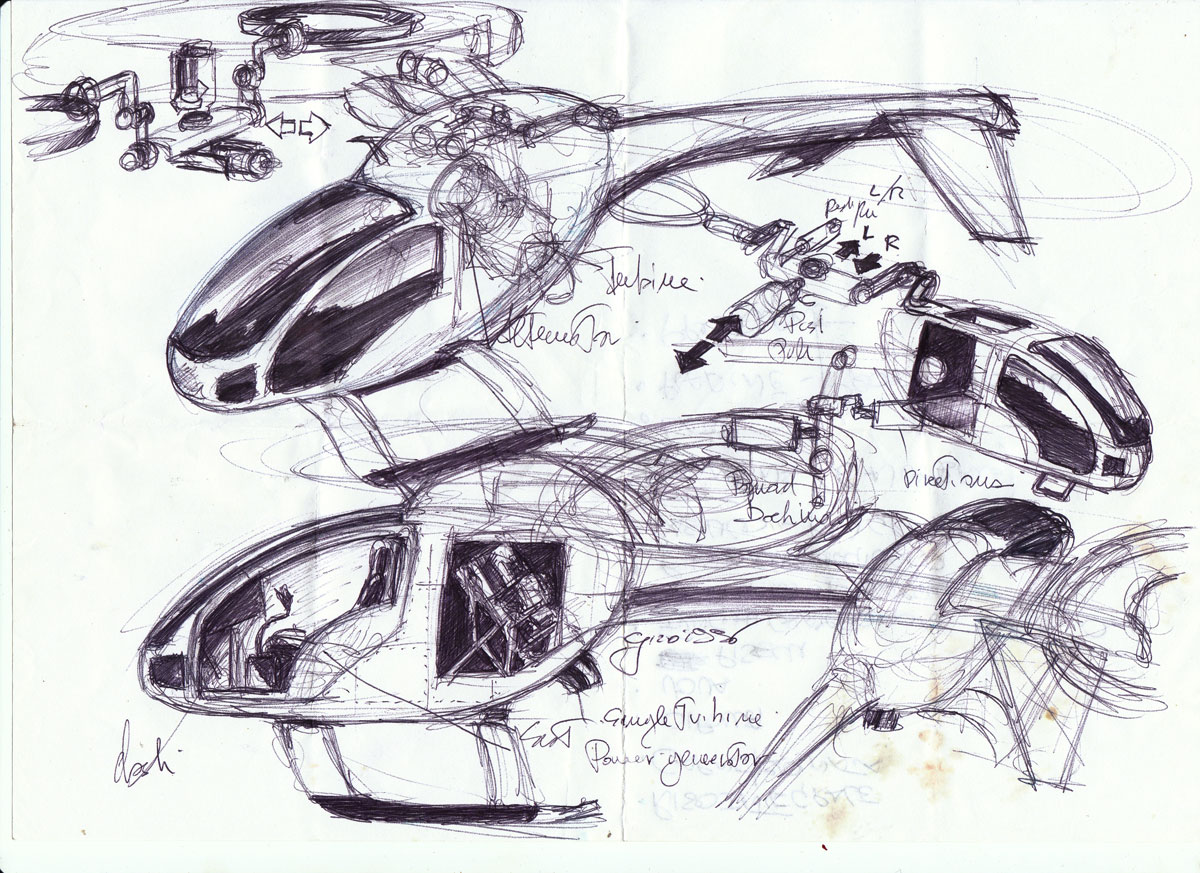

1995-96 was the year when this project born, it was the first hybrid helicopter concept having an interesting and very intriguing combination between electric motors and a turbine power generator. This compact power-plant could produces enough power to power-up the entire system; electric rotor (electro-rotors) included. There wasn’t a unique stimulus which stimulated the development of this project, the aircraft in-fact was designed thanks to a sequence of events, that toke me later to draw the shape of a puzzle-like, combining together a number of ideas that converged at the end in this unique aircraft, and subsequently to the more performing quad-rotors project classified as CellCraft.

Here

the story. I was boarding for a scheduled flight one day, crossing the

parking area together with other passengers going toward the aircraft,

that was standing waiting to be up-loaded of humans and goods. While keeping

walking toward the tail of the plan; since that was on our course, I started

to look at the aircraft very careful as I do every time, looking for details

that can spark my imagination. While doing so being so close to that big

Boeing 767 when the sound of the generator, the APU

attracted my attention. A small metal tube for the exhaust gas warmed

the air, emitting a shriek deaf that was dumped by the gas turbine generator

of the big plane.

The APU (Auxiliary Power Unit)

is always housed in the tail section of jet planes and suddenly it came

to me like a sort of Archimede’s flash strange

idea. I’ve found the right solution for the project of my Helicopter

provided of electric ducted rotors;

a project which I was working for a while, getting lost in some unsolved

technical problem; apparently without any practical solution.

Of course, I’d already had knowledge from long time about APUs I knew perfectly the structure of the APU; some large helicopters are equipped with it, but I’d never thought of adapting it to a different use, and my electric helicopter now got the right answer. It was clear now that since that moment all my projects to come from flying things down to cars, CellCraft included, all, were equipped with a system like this. The combination of a generator and electric motors is from my point of view a sort of perfect power plant, that would solve most of the problems that plagued my imagination since then, obviously talking about my projects.

At that time, we pilots used to spend some of our free time chatting or smoking a cigarette, relaxing down the parking lot. There was a colleague of ours, a Japanese guy, Makoto Higarashi, often returning from Japan submitted as a sort of joke to us some interesting - and most of the time - very smart inventions, inviting us to guess the purpose of one of his mysterious japanese toys.

One day he brought a small folded electric scooter, contained in a compact briefcase, it could be “unfolded” within few seconds, be setled on the groud allowing every one there to run for a couple of minutes, having a lot of fun sitted on that damn littel running thing.

I saw a similar item appear few years later in Italy too, but it was that episode of that morning in the April of 1992 that first stimulated the idea about an electric helicopter, and since then I started working on several prototypes, having a reference poit like the R22 which I knew in any single detail, but that later became something else.

The

idea of course I imagined and sketched with my colored pens, was since

then to conceive a full electric helicopter provided of electric motors,

perhaps powered by a battery system or any other powerful source, but

capable to produce enough electricity to make it flying. Unfortunately

I realized soon that it was quite impossible in those years going forward

with a such crazy idea. There weren’t yet any type of batteries

I needed for my helicopter, and those available at the time were quite

heavy having a very short autonomy. All that was frustrating and turned

my project in a stupid and imaginary exercise, since I wouldn’t

never find a reasonable solution for the problem; at least not until 1996.

Of course there were some advantages, no more transmission; maintenance

as simple as possible, low noise and other positive aspects. And all this

stimulated me every time I thought about that, wishing to go back again

on the idea. So I opened up my archive trying to make some more sketches

or writing some new idea, that I thought could be useful for the meaning

of the projects, and that project was frequently subject to periodical

check. I changed always a detail in some way in order to improve the quality

of the originary concept, always hoping that suddenly a some kind of crazy

idea would come out. But every time the experience ended-up and I stored

the sketches and everything was related to it, including descriptions

in the project’s folder freezing once again that insane idea. What

really wonder me still today is that few years later, the right answer

didn’t came out from my paper and my pens, but rather from the tail

of a B767.

The APU is instead formed by a small turbine engine, connected with an electric generator, which is connected to a control system and distribution device of the electric power, which is injected in the electric network of the aircraft. This small power plant is kept always running even for a while after take-off and then be switched off, since the main engines provide for the necessary power for the aircraft throughout the whole flight. The APU will then be restarted shortly before landing, or once the aircraft is already on the ground.

For

some years both, computers and software of all kind began to invade the

daily activities of all of us. Graphics performances

became more and more elaborate and CPU and memories more and more advanced

and powerful. You could think of a device able to manage the whole system

of APU combined with efficient electro-rotors,

perhaps through a digital system managed by an efficient and smart software.

So my idea was always since the beginning to develope a technological

combination consisted of a turbine-gas-generator connected through an

electronic digital control with four electrical motors mounted on independent

rotors. This would allow me to design a machine rather interesting, a

transmission-less aircraft, replacing that complex and heavy gear boxes

with cables, instead than heavy shafts, and that would offer a number

of endless possibilities, making this aircraft a unique example by many

points of view.

Too many switches scattered everywhere, as well lights and many indicators seemed to me pretty much obsolete, making the scanning operations pretty much uncomfortable, particularly for helicopter, since pilot works a lot looking outside the cockpit.

The power and the great flexibility of computers once again could help me to solve problems of architectural and “interactive relationship” between the pilot and the machine.

Why should we fly having so many gauges, switches, light of various types, if all the information about motors or navigation systems can be summarized simply projecting them on a single screen (Technology already available at that time). I based all my project on the available technology and its future developments in order to design the best aircraft every time. Indeed Some years later I started to consider a review of the originary project, the DDRH in a new modern one, having a new electro-rotors, new controls, new electronics, and dual MPU unit. It was the time the DDVL was born.

The new concept of the cockpit was the root of this project, because as already written before, my initial goal was to redraw the entire cockpit of a classic helicopter from the beginning, and then go over to the aircraft itself, more and more elaborate as it was then, becoming later to develop CellCraft’s projects.

Electronics

The

cockpit of the DDRH/DDVL was

provided with a single LCD display that projected all

the necessary information related to the navigation, as well those about

gas turbine(MPU), generator etc.

It wasn’t a touch screen like those today we are all familiar with,

even though at that time it worked in amore simple way. Although some

basic functions would be activated by pressing certain areas of the screen.

In 1996 some type of primitive tactile screen were covered

with a fine transparent special film, it was made of a sort of invisible

grid which allowed to switch On or Off numerous functions displayed on

the LCD screen, which was placed right behind the grid. The DDRH

was in-fact equipped with such device, that a that time was the top of

the available electronic technologies of that kind. A second front console

with conventional backlighting switches guaranteed the management of other

aircraft's systems. The cockpit therefore had become a compact and easy

tool to manage, just as mean since the beginning, although it was still

far from the idea that later - with the CellCraft’s series

- will be developed, with real and more efficient touch screens and smart,

flexible and interactive software, wich was installed in the most recent

DDVL's aircraft.

The helicopter was provvided of a small turbo-generator capable to generate

a power of about 240 hp (178Kw) 100% output power, while

the four electric motors were housed in pairs of two inside special shells,

in the DDRH, while the DDVL was provided only of two electric motors,

more compact and powerful, directly connected with the two (five

blades) rotors. The electro-rotors could absorb a maximum

output power not exceeding of 220kw (295Cv)

each, enough power to guarantee a safe and comfortable flight based

on high-quality performance of the aircraft.

The digital control system was housed in the central compartment which

included an inverter and a special battery capable of ensuring a constant

flight between 7 and 10 minutes in case of engine failure.

The rotor blades were of carbon fiber covering the aluminum core, they were mounted on an articulated bearing act to ensure the variation of the collective blade pitch through an electro-controlled mechanism hidden inside the upper disk of each rotor.

The power supply system of the motors occured through a digital device, (ESC) injecting electric pulses with variable frequency to each one of the three-phase induction motors. This guaranteed a precision of rotation and a perfect and constant power well distribuited on both rotors. Also the control system the AFC (Automatic-Flight-Control) was capable to manage each of the rotor independently, modifying both rotor Rpm as well pitch angle of the blades, according with the asset that the aircraft assumed during the flight, in order to guarantee the stability of the helicopter in any flight condiction.

The DDRH as well the DDVL was a single-seat helicopter, however, the cockpit was quite wide and handy, allowed a very good visibility thanks to the wide lateral windows. The one on the right was the only one which worked as main door, allowing a clear access to the cockpit. All controls and levers; the collective control; the pedals and the cloche were all servo assisted through doubled electromechanical systems having two independent circuits, having a classic helicopter configuration, differently by the DDVL, which instead is provided of two main joystick on each side as fly-by-wire device, similiar to those installed on CellCraft and EJ's projects.

The DDRH/DDVL's rotors looks pretty much different from that of a common helicopter. They are capable of a tilting movement that can reach a maximum excursion up to 15° either forward or backward. Rotors are not provided of any cyclic plate, having only a collective pitch control.

Lateral

shifting could be done through the collective variation of the two rotors

which produced a different thrust between them. To be able to move while

in flight the machine sideways, pilot would just tilt the lever of the

desired directional, exactly like happens handling a conventional ciclic.

The control system (AFC) then, will reduce the collective

pitch of the rotor on the one side, by increasing it in the same percentage

of that on the opposite side. This will cause a lateral displacement of

the aircraft in a given direction.

To shift forwards the aircraft instead, pilot would tilt slightly forward

the directional control. The AFC will then tilt forward

both rotors in such way, that the thrust created a vector which move gently

the helicopter forward or backward. There was also the possibility to

vary the rotation of the rotors for a limited percentage, but this was

done under particular conditions, where the requirement of maximum power

were necessary as in lift-up operation. This job was done through the

relatively complex computer that control both the electric-rotors

and the turbine gas generator.

Each rotor shell contained two three-phase motors(DDRH) or one three-phase motor connected each other on a single main shaft to the rotor disk, which is provided of a five-blade with a collective articulation system. Motors were air cooled through a front vents opened in the front area of the rotor cowling (DDRH) or self-ventilated (DDVL). On the head of both rotors there was inserted an electromechanical mechanism act to the variation of collective pitch; it was designed as to be a very fine and a rapid responsing device.

The DDRH was the beginning of a series of projects very indicative; the CellCraft among the most important come from this original idea. This project led me gradually over the time to combine my experience as a pilot with that of aircraft designer. Most of my projects - should they run on the road or fly in the sky - are always conceived taking very seriously the combination between technology and environment. So electronics; computers; electrical systems; low impact energy production system and finally electric motors, particularly the latest generation ones, combined with high performance software, highly smart and flexible, all that replacing complex and heavy transmission mechanisms, which; pheraphs;.... maybe, will give you the chance to get a very intriguing vehicle, whatever its application should be. Design machines like these would reduce the complexity of the design as well maintenance’s cost and finally the amount of energy applied.

Today

the technology available allows us to design and build machines highly

efficient, very compact and quite simple. Right now we are moving from

the mechanical era to the electric one, as technology develops, covering

distances even more longer is always a matter of seconds; of-course “digitally”

speaking. Aircraft like these however could cover “physically”

long distances or get in areas that are often even today still inaccessible.

Ducted rotor helicopters or even more complex aircraft like the CellCraft

were design also for this porpoise.

|